Measurement of Acceleration Response Functions with Scalable Low-Cost Devices. An Application to the Experimental Modal Analysis

Abstract

:1. Introduction

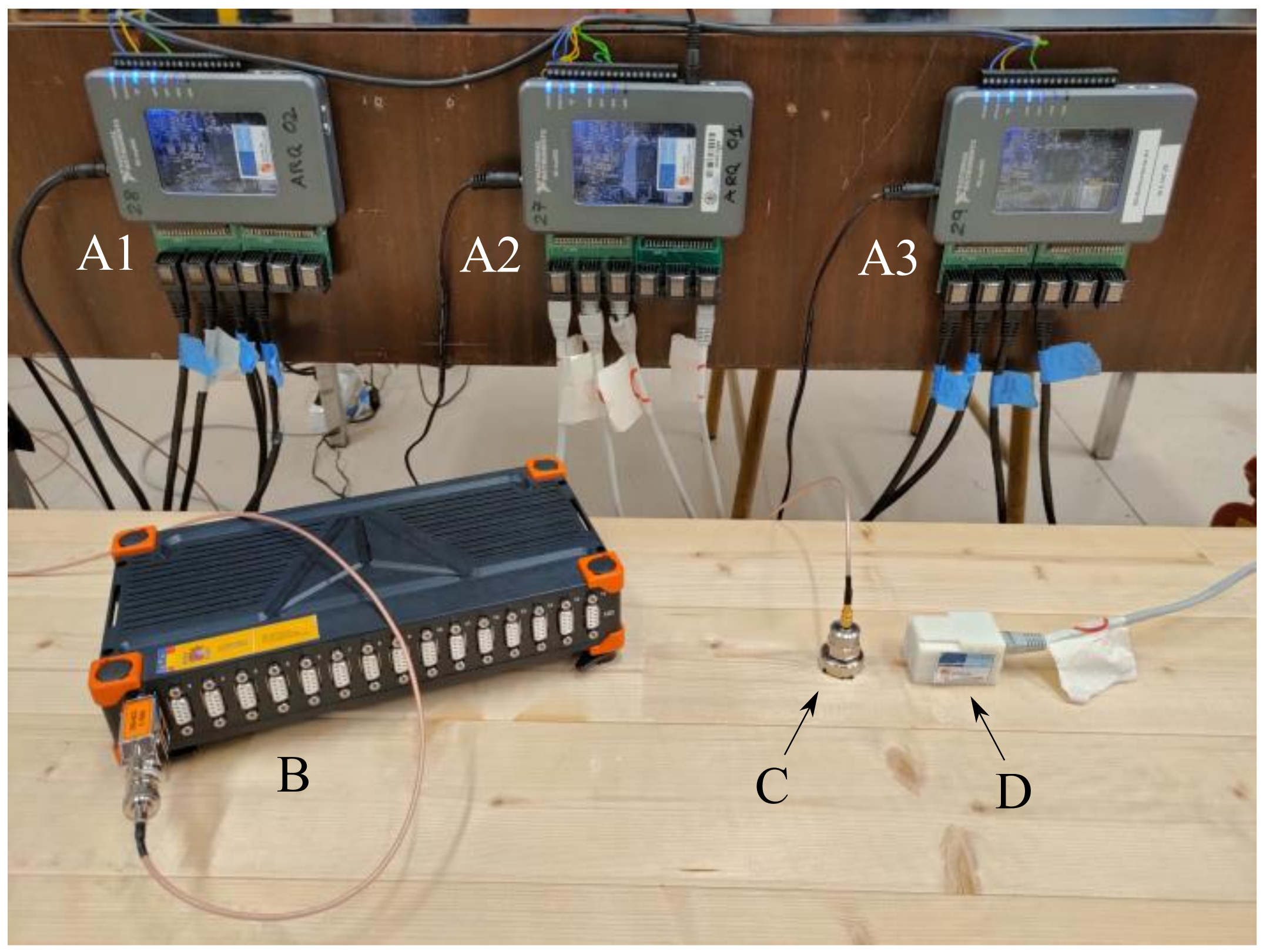

2. Monitoring System Description

2.1. System Architecture

2.2. System Synchronization

3. Validation of the Proposed Distributed System: Synchronization

3.1. Reference System

3.2. Synchronization Tests

4. Validation of the Proposed Distributed System: Modal Analysis

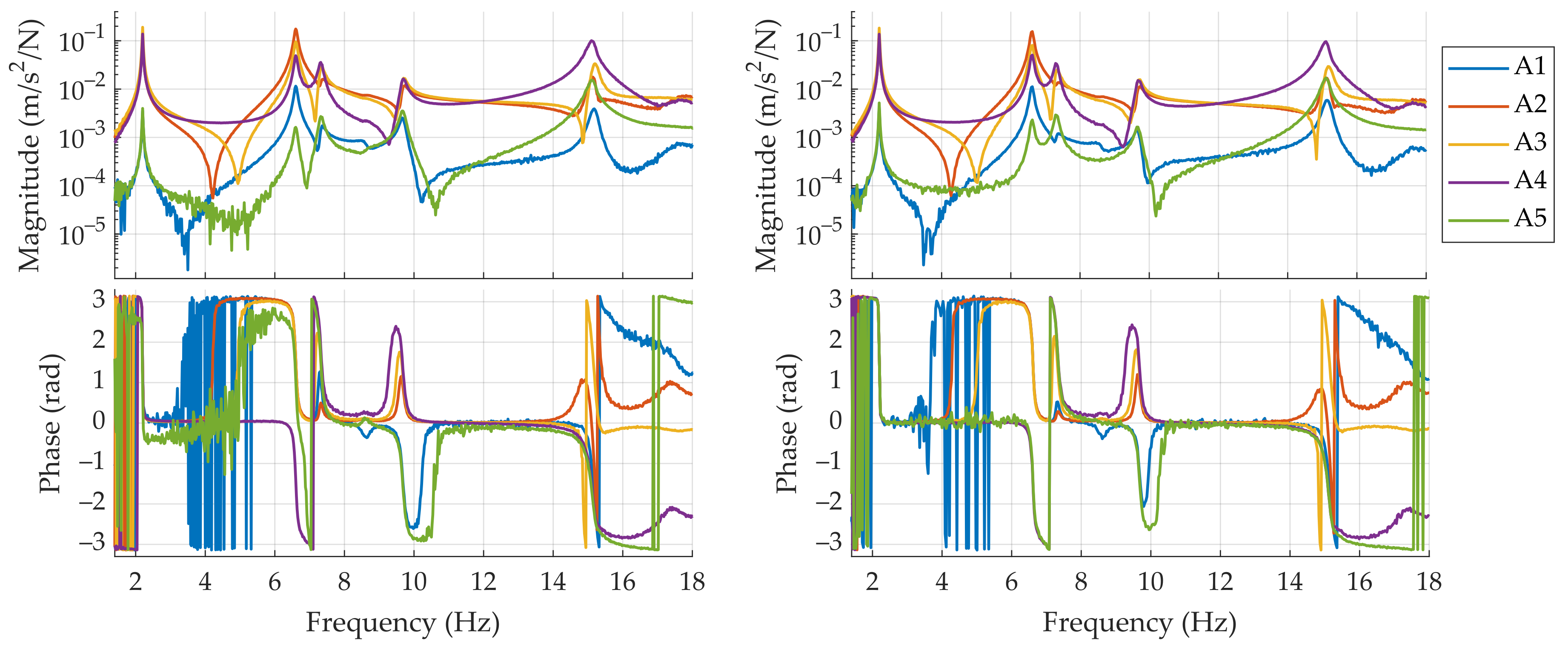

4.1. Measurement Layout and FRF Estimation for Modal Analysis

4.2. Modal Analysis Procedures

4.2.1. Proposed System Identification Method (FDPI)

4.2.2. Reference System Identification Method (CF)

4.3. Results Comparison

5. Conclusions

- The low-cost system consisting of three myRIOs and twelve MEMS accelerometers has been installed on a structure in parallel to other more sophisticated reference system, commercially available for modal analysis purposes.

- After recording the time domain signals and calculating the associate Frequency Response Functions, the modal parameters of the structure have been estimated by different means: a robust but slow and computationally resource-intensive algorithm has been used to process the reference data within the MATLAB environment, whilst a simpler algorithm, implemented in the LabVIEW environment, has been used to process the low-cost system data.

- Due to the high synchronization attained by means of the proposed system, the modal properties estimated with it are similar to the ones estimated by using the commercial hardware and software, with relative errors under 1.1% for the natural frequencies and under 17% for the damping ratios.

- The mode shapes have been compared via the Modal Assurance Criterion, obtaining values above 0.95 in all cases.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ye, X.W.; Jin, T.; Yun, C.B. A review on deep learning-based structural health monitoring of civil infrastructures. Smart Struct. Syst. 2019, 24, 567–585. [Google Scholar] [CrossRef]

- Farrar, C.R.; Doebling, S.W.; Nix, D.A. Vibration–based structural damage identification. Philos. Trans. R. Soc. A: Math. Phys. Eng. Sci. 2001, 359, 131–149. [Google Scholar] [CrossRef]

- Mahammad, A.H.; Kamrul, H.; Ker, P.J. A review on sensors and systems in structural health monitoring: Current issues and challenges. Smart Struct. Syst. 2018, 2, 509–525. [Google Scholar] [CrossRef]

- Farrar, C.; Worden, K. An introduction to structural health monitoring. Philos. Trans. R. Soc. A: Math. Phys. Eng. Sci. 2006, 365, 303–315. [Google Scholar] [CrossRef]

- Matos, J.C.E.; García, O.; Henriques, A.A.; Casas, J.R.; Vehí, J. Health Monitoring System (HMS) for structural assessment. Smart Struct. Syst. 2009, 5, 223–240. [Google Scholar] [CrossRef]

- Soria, J.M.; Diaz, I.M.; Garcia-Palacios, J.H.; Iban, N. Vibration monitoring of a steel-plated stress-ribbon footbridge: Uncer-tainties in the modal estimation. J. Bridge Eng. 2016, 21, C5015002. [Google Scholar] [CrossRef] [Green Version]

- Girolami, A.; Brunelli, D.; Benini, L. Low-cost and distributed health monitoring system for critical buildings. In Proceedings of the 2017 IEEE Workshop on Environmental, Energy, and Structural Monitoring Systems (EESMS), Milan, Italy, 24–25 July 2017; Institute of Electrical and Electronics Engineers (IEEE): New York, NY, USA, 2017; pp. 1–6. [Google Scholar]

- Salawu, O. Detection of structural damage through changes in frequency: A review. Eng. Struct. 1997, 19, 718–723. [Google Scholar] [CrossRef]

- Goyal, D.; Pabla, B. Development of non-contact structural health monitoring system for machine tools. J. Appl. Res. Technol. 2016, 14, 245–258. [Google Scholar] [CrossRef]

- Swartz, R.A.; Lynch, J.P.; Zerbst, S.; Sweetman, B.; Rolfes, R. Structural monitoring of wind turbines using wireless sensor networks. Smart Struct. Syst. 2010, 6, 183–196. [Google Scholar] [CrossRef] [Green Version]

- Gomez, H.C.; Fanning, P.J.; Feng, M.Q.; Lee, S. Testing and long-term monitoring of a curved concrete box girder bridge. Eng. Struct. 2011, 33, 2861–2869. [Google Scholar] [CrossRef] [Green Version]

- Moser, P.; Moaveni, B. Design and Deployment of a Continuous Monitoring System for the Dowling Hall Footbridge. Exp. Tech. 2011, 37, 15–26. [Google Scholar] [CrossRef]

- Waidyanatha, N. Towards a typology of integrated functional early warning systems. Int. J. Crit. Infrastructures 2010, 6, 31. [Google Scholar] [CrossRef]

- Hu, C.; Xiao, M.; Zhou, H.; Wen, W.; Yun, H. Damage detection of wood beams using the differences in local modal flexibility. J. Wood Sci. 2011, 57, 479–483. [Google Scholar] [CrossRef]

- Ribeiro, R.R.; Lameiras, R.D.M. Evaluation of low-cost MEMS accelerometers for SHM: Frequency and damping identification of civil structures. Lat. Am. J. Solids Struct. 2019, 16. [Google Scholar] [CrossRef] [Green Version]

- Acar, C.; Shkel, A.M. Experimental evaluation and comparative analysis of commercial variable-capacitance MEMS accelerometers. J. Micromechanics Microengineering 2003, 13, 634–645. [Google Scholar] [CrossRef] [Green Version]

- Zhu, L.; Fu, Y.; Chow, R.; Spencer, B.F.; Park, J.W.; Mechitov, K.; Zhu, L.; Fu, Y.; Chow, R.; Spencer, B.F.; et al. Development of a High-Sensitivity Wireless Accelerometer for Structural Health Monitoring. Sensors 2018, 18, 262. [Google Scholar] [CrossRef] [PubMed]

- Villacorta, J.; Del-Val, L.; Martínez, R.; Balmori, J.-A.; Magdaleno, Á.; López, G.; Izquierdo, A.; Lorenzana, A.; Basterra, L.-A. Design and Validation of a Scalable, Reconfigurable and Low-Cost Structural Health Monitoring System. Sensors 2021, 21, 648. [Google Scholar] [CrossRef] [PubMed]

- Dos Santos, F.L.M.; Peeters, B.; Lau, J.; Desmet, W.; Góes, L.C.S. The use of strain gauges in vibration-based damage detection. J. Phys. Conf. Ser. 2015, 628, 12119. [Google Scholar] [CrossRef] [Green Version]

- Dos Reis, J.; Costa, C.O.; Da Costa, J.S. Strain gauges debonding fault detection for structural health monitoring. Struct. Control. Health Monit. 2018, 25, e2264. [Google Scholar] [CrossRef]

- Moreu, F.; Jo, H.; Li, J.; Kim, R.E.; Cho, S.; Kimmle, A.; Scola, S.; Le, H.; Spencer, J.B.F.; LaFave, J.M. Dynamic Assessment of Timber Railroad Bridges Using Displacements. J. Bridg. Eng. 2015, 20, 4014114. [Google Scholar] [CrossRef]

- Moschas, F.; Stiros, S. Measurement of the dynamic displacements and of the modal frequencies of a short-span pedestrian bridge using GPS and an accelerometer. Eng. Struct. 2010, 33, 10–17. [Google Scholar] [CrossRef]

- Guzman-Acevedo, G.M.; Vazquez, E.; Millan-Almaraz, J.R.; Rodriguez-Lozoya, H.E.; Reyes-Salazar, A.; Gaxiola-Camacho, J.R.; Félix, C.A.M. GPS, Accelerometer, and Smartphone Fused Smart Sensor for SHM on Real-Scale Bridges. Adv. Civ. Eng. 2019, 2019, 6429430. [Google Scholar] [CrossRef]

- Shajihan, S.A.V.; Chow, R.; Mechitov, K.; Fu, Y.; Hoang, T.; Spencer, J.B.F. Development of Synchronized High-Sensitivity Wireless Accelerometer for Structural Health Monitoring. Sensors 2020, 20, 4169. [Google Scholar] [CrossRef] [PubMed]

- Bocca, M.; Eriksson, L.M.; Mahmood, A.; Jäntti, R.; Kullaa, J. A Synchronized Wireless Sensor Network for Experimental Modal Analysis in Structural Health Monitoring. Comput. Civ. Infrastruct. Eng. 2011, 26, 483–499. [Google Scholar] [CrossRef]

- Zonzini, F.; Malatesta, M.M.; Bogomolov, D.; Testoni, N.; Marzani, A.; De Marchi, L. Vibration-based SHM with up-scalable and low-cost Sensor Networks. IEEE Trans. Instrum. Meas. 2020, 69, 7990–7998. [Google Scholar] [CrossRef]

- Klingensmith, B.; Campbell, T.; Feng, M.Y.; Ghazi, R.M.; Büyüköztürk, O. Highly synchronized, simultaneous, high-speed 24-bit data acquisition of triaxial MEMS accelerometers for monitoring a real world civil structure. In Proceedings of the 2014 IEEE AUTOTEST, St. Louis, MO, USA, 15–18 September 2014; Institute of Electrical and Electronics Engineers (IEEE): New York, NY, USA, 2014; pp. 142–149. [Google Scholar]

- DS-SIRIUS Data-Logger. Available online: https://dewesoft.com/products/daq-systems/sirius (accessed on 26 June 2021).

- Palma, P.; Steiger, R. Structural health monitoring of timber structures—Review of available methods and case studies. Constr. Build. Mater. 2020, 248, 118528. [Google Scholar] [CrossRef]

- Mahini, S.S.; Moore, J.C.; Glencross-Grant, R. Monitoring timber beam bridge structural reliability in regional Australia. J. Civ. Struct. Health Monit. 2016, 6, 751–761. [Google Scholar] [CrossRef]

- ADXL355 3-Axis MEMS Accelerometer. Available online: https://www.analog.com/media/en/technical-documentation/data-sheets/adxl354_355.pdf (accessed on 12 May 2020).

- User Guide and Specifications NI myRIO-1900. Available online: https://www.ni.com/pdf/manuals/376047c.pdf (accessed on 19 November 2020).

- Hennig, W.; Tan, H.; Walby, M.; Grudberg, P.; Fallu-Labruyere, A.; Warburton, W.; Vaman, C.; Starosta, K.; Miller, D. Clock and trigger synchronization between several chassis of digital data acquisition modules. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 2007, 261, 1000–1004. [Google Scholar] [CrossRef]

- KS76C.100 IEPE Accelerometers. Available online: https://mmf.de/standard_accelerometers.htm (accessed on 26 June 2021).

- Böswald, M.; Göge, D.; Füllekrug, U.; Govers, Y. A review of experimental modal analysis methods with respect to their ap-plicability to test data of large aircraft structures. In Proceedings of the 2006 International Conference on Noise and Vibration Engineering (ISMA 2006), Heverlee, Belgium, 18–20 September 2006; pp. 2461–2482. [Google Scholar]

- Lembregts, F.; Leuridan, J.; Van Brussel, H. Frequency domain direct parameter identification for modal analysis: State space formulation. Mech. Syst. Signal Process. 1990, 4, 65–75. [Google Scholar] [CrossRef]

- Ewins, D.J. Modal Testing: Theory, Practice and Application, 2nd ed; Research Studies Press: Baldock, UK, 2000. [Google Scholar]

- Maia, N.; Silva, J. Theoretical and Experimental Modal Analysis; Engineering Dynamics Series; Research Studies Press: Baldock, UK, 1997. [Google Scholar]

| Characteristic | Proposed System | Reference System |

|---|---|---|

| Accel. range | ±2 g, ±4 g, and ±8 g | ±60 g |

| Accel. digital sensitivity | 3.9, 7.8 and 15.6 μg/LSB | 11.9 μg/LSB |

| Accel. noise density | 25 µg/√Hz | 3 µg/√Hz |

| Max. sample frequency | 4 kHz | 200 kHz |

| Bits per sample | 20 | 24 |

| Max. accelerometer channels | 6 tri-axial per device | 16 uni-axial |

| Total cost (device + 6 accels) | €928 per device | €9050 per device |

| Delay (ns) | ||||

|---|---|---|---|---|

| Mean | Min | Max | Std. Dev. | |

| Sync clock-Master unit | 48.92 | 45.54 | 62.73 | 1.13 |

| Sync clock-Slave unit 1 | 51.36 | 46.54 | 63.44 | 1.57 |

| Sync clock-Slave unit 2 | 54.39 | 49.22 | 65.70 | 1.40 |

| Master unit-Slave unit 1 | 2.43 | −4.53 | 7.81 | 2.11 |

| Master unit-Slave unit 2 | 5.46 | −1.47 | 9.92 | 1.96 |

| Delay (ns) | ||||

|---|---|---|---|---|

| Mean | Min | Max | Std. Dev | |

| Sync clock-Master unit | 40.04 | 38.75 | 57.27 | 1.47 |

| Sync clock-Slave unit 1 | 79.67 | 74.92 | 83.78 | 1.50 |

| Sync clock-Slave unit 2 | 90.74 | 87.77 | 93.44 | 1.00 |

| Master unit-Slave unit 1 | 39.62 | 35.23 | 43.60 | 2.25 |

| Master unit-Slave unit 2 | 50.703 | 41.69 | 53.16 | 1.72 |

| Mode | Natural Frequency (Hz) | Damping Ratio (%) | MAC | ||||

|---|---|---|---|---|---|---|---|

| CF | FDPI | Error (%) | CF | FDPI | Error (%) | ||

| 1 | 2.198 | 2.190 | −0.377 | 0.389 | 0.436 | 11.9 | 0.999 |

| 2 | 6.602 | 6.600 | −0.0492 | 0.709 | 0.744 | 4.91 | 0.997 |

| 3 | 7.324 | 7.361 | 0.508 | 0.910 | 1.05 | 15.4 | 0.981 |

| 4 | 9.685 | 9.669 | −0.165 | 0.802 | 0.812 | 1.35 | 0.995 |

| 5 | 15.07 | 15.05 | −0.135 | 0.931 | 0.779 | −16.3 | 0.994 |

| 6 | 24.15 | 24.14 | −0.0374 | 0.684 | 0.674 | −1.55 | 0.942 |

| 7 | 26.79 | 26.71 | −0.324 | 1.10 | 1.08 | −2.10 | 0.973 |

| 8 | 28.23 | 28.06 | −0.599 | 1.08 | 1.20 | 10.6 | 0.953 |

| 9 | 39.56 | 39.13 | −1.08 | 0.977 | 1.02 | 4.80 | 0.989 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Magdaleno, A.; Villacorta, J.J.; del-Val, L.; Izquierdo, A.; Lorenzana, A. Measurement of Acceleration Response Functions with Scalable Low-Cost Devices. An Application to the Experimental Modal Analysis. Sensors 2021, 21, 6637. https://doi.org/10.3390/s21196637

Magdaleno A, Villacorta JJ, del-Val L, Izquierdo A, Lorenzana A. Measurement of Acceleration Response Functions with Scalable Low-Cost Devices. An Application to the Experimental Modal Analysis. Sensors. 2021; 21(19):6637. https://doi.org/10.3390/s21196637

Chicago/Turabian StyleMagdaleno, Alvaro, Juan J. Villacorta, Lara del-Val, Alberto Izquierdo, and Antolin Lorenzana. 2021. "Measurement of Acceleration Response Functions with Scalable Low-Cost Devices. An Application to the Experimental Modal Analysis" Sensors 21, no. 19: 6637. https://doi.org/10.3390/s21196637

APA StyleMagdaleno, A., Villacorta, J. J., del-Val, L., Izquierdo, A., & Lorenzana, A. (2021). Measurement of Acceleration Response Functions with Scalable Low-Cost Devices. An Application to the Experimental Modal Analysis. Sensors, 21(19), 6637. https://doi.org/10.3390/s21196637